Replacement shift rod bushing, 1981 VW Vanagon.

The shift rod bushing on my bus finally failed. I could still shift, but it was sloppy, and the shift rod would rattle while driving. The bushing is No Longer Available from VW, and it's $25 for a reproduction made of similar soft plastic.

The old, failed bushing.

So, I decided to make something better, which would hopefully last much longer than the VW design. I got a chunk of ~1" thick acetal plastic (Delrin, polyoxymethylene), which is easily machined, quite tough, and self-lubricating. Perfect for this application.

The shift rod on my '81 Vanagon is 18mm in diameter (they changed the size around '85?). A 23/32" drill is 18.26mm in diameter - perfect, just enough extra to let things move easily. So, after a bit of measuring, machining and fitting:

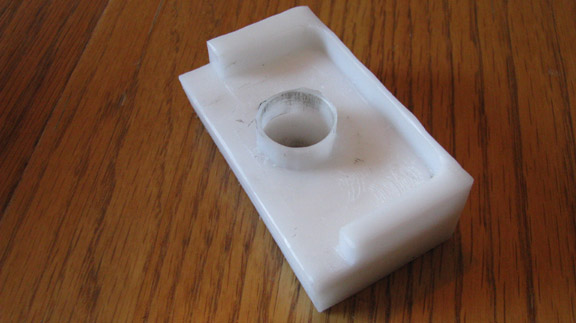

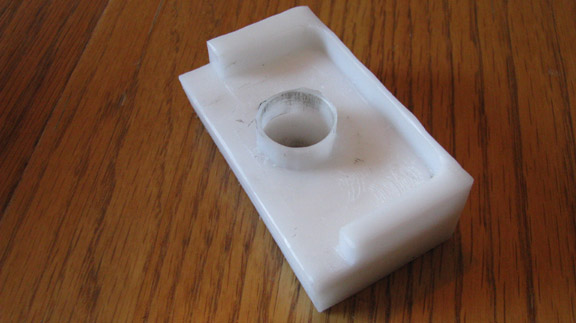

The completed replacement bushing

I "walked" the mill around the hole, leaving rim of plastic which would fit through the hole in the mounting bracket. Sloppy, but good enough. It wasn't really necessary, but made final fitting a bit easier. Same with the raised edges, which surround the VW bracket. I only milled about 1/4" away, so there's still a lot of thickness left. Here's the basic layout:

Another view.

When drilling the hole, it's important to know that the shift rod doesn't go through square. It is angled slightly downward as it goes from the front to the rear of the bus. It also angles slightly from left to right. If you drill the hole square, the rod will bind unless you shim the bushing when mounting it. I got the up/down angle right, but didn't consider the left/right. I used a washer between the new bushing and the bracket to shim it slightly, and everything was good.

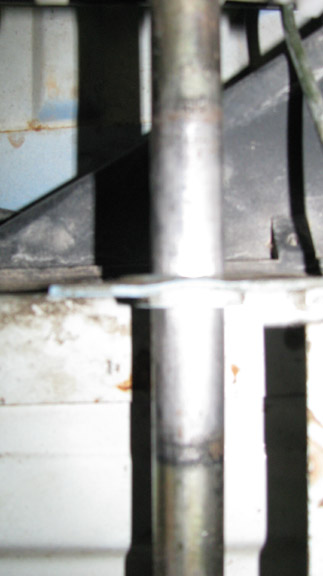

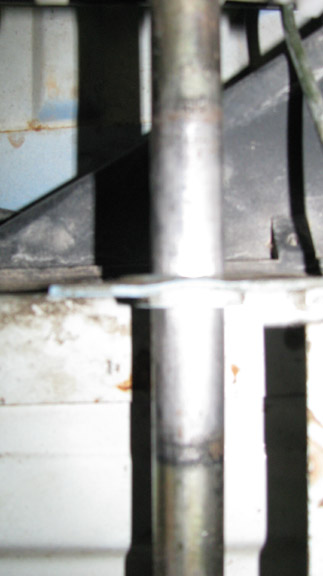

The shift rod. Top is front. You might notice that the rod angles slightly from the driver's side (right in this picture) toward the passenger side. I didn't.

To mount it, I drilled a couple of 3/16" holes in the original bracket, and used #10 stainless steel sheet metal screws. Acetal isn't like wood, you need a good sized pilot hole for the screws. I think I ended up using a #18 drill. Anything smaller, and the screws would get very difficult to turn after only a couple of turns. That's why the screw heads are munged up a bit.

Installed, and ready to drive.

It works great, and should last just about forever.